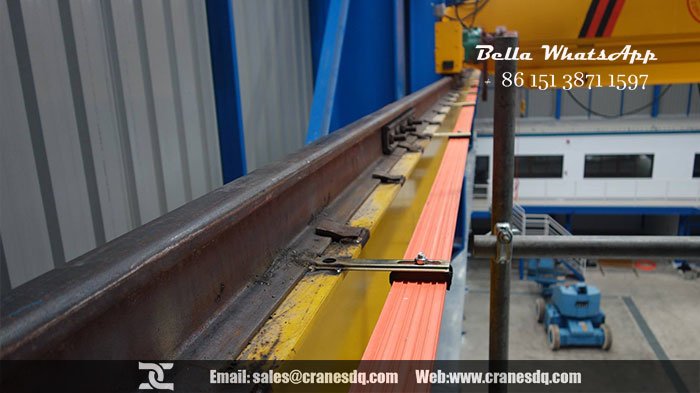

Calculations based on measured data with proprietary analysis and visualization software.Measurement of the alignment of your crane runway.A visual inspection of the crane runway.RailQ can be performed on virtually any runway including those for overhead cranes, port cranes and woodyard cranes. What’s included in a RailQ Runway Survey? RailQ uses a remotely operated robot to minimize downtime and increase the safety of the survey. It provides information on runway span, straightness, elevation and rail-to-rail elevation. However, these surveys may result in days of costly downtime, and the results may not be accurate or clear and may not offer corrective actions. Improper tracking is normally investigated by performing a traditional runway survey. Runway structure is uneven, bent or twisted due to column settlement, overloads or impacts.There are many reasons why a crane does not travel correctly on the runway: Improper tracking leads to premature wheel and rail wear, resulting in costly repairs and downtime, as well as inefficient and suboptimal crane operation. Is your crane traveling correctly on the runway?Ĭranes should travel or track along their runway rails with a minimum of skew and without binding. The RailQ Runway Survey has been designed to deliver accurate information on the alignment of your crane rail and expert recommendations for any needed corrective actions. If your crane is experiencing excessive wear on wheels and rails, has broken wheel flanges, or you’re frequently replacing bridge couplings and axles – you may need to take a deeper look at rail alignment. Christoph Basser, Inside Sales/Estimator.Amina Peerzade, Siebel IT Administrator.Matilda Petersson, Agreement Sales Director.

Juha Anttila, Director, Portfolio Management Office, IT.Digital tool information on yourKONECRANES.TRUCONNECT information on yourKONECRANES.

0 kommentar(er)

0 kommentar(er)